Freeze Protecting Your Pressure Vacuum Breaker

Freezing? Protect Your Vacuum Breaker (Backflow) the Right Way

Outdoor vacuum breakers / backflow preventers on irrigation systems can crack with the first hard freeze. A few quick steps—drain, isolate, insulate—prevent costly spring repairs. Here’s how to winterize a typical PVB (pressure vacuum breaker) or above-grade backflow assembly and what to check at spring start-up.

When to Winterize

- Before nightly lows hit 32°F (0°C) for more than a few hours.

- If a surprise cold snap is coming, do the quick drain steps below and add an insulating cover the same day.

What You’ll Need

- Flat screwdriver or test-cock key

- Adjustable wrench (for unions/bonnets if servicing)

- Insulated backflow cover or enclosure

- Shop towels/bucket

Winterize in Minutes (Most PVB/Above-Grade Assemblies)

- Shut off irrigation water at the supply valve feeding the backflow (usually a ball valve below/behind the assembly).

- Open downstream valves (zones) to relieve pressure. If you have manual drains, open those too.

- Open test cocks on the backflow ¼–½ turn to vent and drain. Keep them angled slightly down so water escapes.

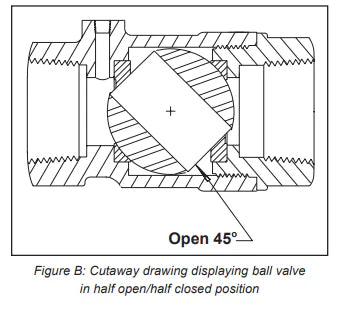

- Set the shutoff handles at 45° (half-open) so trapped water can expand without breaking the body.

- Optional blow-out: If you winterize the whole sprinkler system, connect air after the backflow at the manifold and keep pressure within sprinkler ratings (many pros keep zone blow-outs ≤50 PSI). Do not blast high pressure through the backflow body.

- Insulate & cover: Slip an outdoor-rated insulated cover over the assembly; seal drafts from below. In severe climates, use a listed heat-tape solution per instructions.

Spring Start-Up Checks

- Close test cocks and return shutoff handles to fully open (parallel with pipe).

- Pressurize slowly and inspect for leaks at the bonnet, relief ports, and unions.

- If water vents continuously from the top/relief, inspect/replace bonnet & poppet or check assemblies.

“Shop This Type” Cards

Febco Backflows

Insulated Backflow Covers

Repair Kits (Bonnet/Poppet, Checks)

Code note: Always follow your local plumbing code and manufacturer instructions. Some regions prohibit insulating over test ports without removable access—choose covers that allow service.

Blog posts

-

Choosing a Rinnai Tankless Water Heater: Sizing, Cost, Maintenance & Most-Asked Questions

Read nowThinking Rinnai tankless? This guide answers the most common questions—how to size, how often to flush, typical issues, condensing vs. non-condensing, indoor vs. outdoor, warranties, and more—so you can pick the right model with confidence.

-

Snow-Melt Systems for Walkways, Paths & Driveways (How They Work, Cost, Install & FAQs)

Read nowSnow-melt heating uses embedded electric mats or cables to automatically clear ice and snow from walkways, paths, and driveways—no salt, no scraping. Here’s how it works, when to use it, what it costs, and what to buy.

-

What Is Point-of-Use Reverse Osmosis (RO)? Benefits, Use Cases & FAQs

Read nowPoint-of-use reverse osmosis (under-sink RO) delivers crisp, great-tasting water at the faucet by reducing TDS and chlorine taste/odor—ideal for cooking, coffee, baby formula, and ice—with optional remineralization for those who want minerals/electrolytes back for taste.

Leave a comment